Among common materials, which metal has the best thermal conductivity?

The size of the thermal conductivity of the metal material indicates the size of the thermal conductivity of the metal. The greater the thermal conductivity, the lower the thermal conductivity and the greater the thermal conductivity.

At present, most of the heat sinks or heat sink materials used in electronic devices on the market are almost made of aluminum alloys, and only a few of them use other materials for heat dissipation. But in fact, aluminum is not the metal material with the best thermal conductivity. The best effect is silver, followed by copper, followed by aluminum.

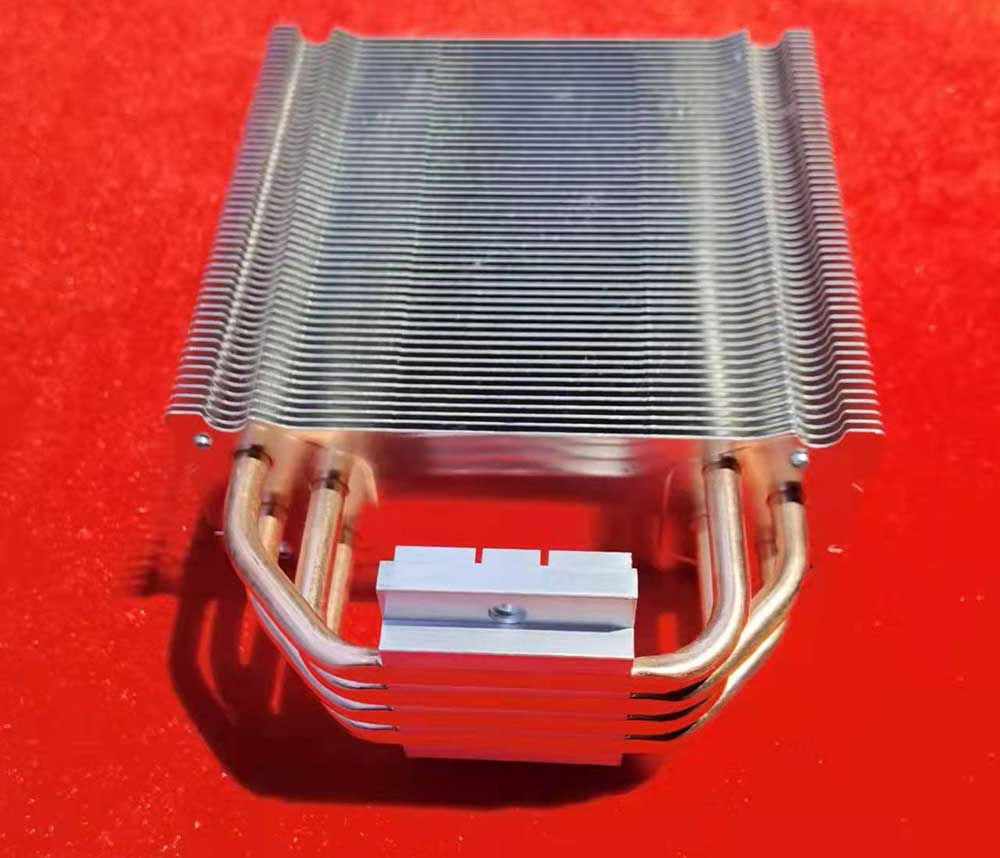

But silver is expensive and unlikely to be used as a heat sink. Pure copper is relatively bulky, but has an advantage in heat dissipation. Now, the combination of aluminum and copper is gradually used in the production of heat sinks. Aluminum is lighter, and can take into account the needs of thermal conductivity, price, and light weight. Therefore, it is generally used as the best material for heat dissipation of electronic parts. Aluminum heat sinks are not 100% pure aluminum, because pure aluminum is too soft, so a small amount of other metals are added and cast into aluminum alloys to obtain appropriate hardness, but aluminum still accounts for about 98%. about.

Copper has unparalleled advantages in industrial applications in thermal conductivity. Yunlan Metal supplies high-quality electronic heat pipes made of copper pipes.

Copper-aluminum combined heat sink: The so-called copper-aluminum combination is a perfect combination of copper and aluminum with a certain process, allowing copper to quickly transfer heat to aluminum, and then dissipate heat by a large area of aluminum, which not only increases Filled with aluminum, the thermal conductivity is not as good as that of copper, and it also makes up for the fact that the heat dissipation of copper is not as good as that of aluminum. The organic combination achieves the effect of rapid heat transfer and rapid heat dissipation.

| metallic material | Thermal Conductivity |

|---|---|

| Silver 99.9% | 411 W/m.K |

| Duralumin 4.5%Cu | 177 W/m.K |

| pure copper | 398 W/m.K |

| Cast aluminum 4.5%Cu | 163 W/m.K |

| gold | 315 W/m.K |

| Mg, 0.6% Mn | 148 W/m.K |

| pure aluminum | 237 W/m.K |

| 6061 aluminum alloy | 155 W/m.K |

| 1070 aluminum alloy | 226 W/m.K |

| Brass 30%Zn | 109 W/m.K |

| 1050 aluminum alloy | 209 W/m.K |

| 6063 aluminum alloy | 201 W/m.K |

| Bronze 25%Sn | 26 W/m.K |

| pure iron | 80 W/m.K |

| tin | 67 W/m.K |

| lead | 34.8 W/m.K |

Most of the heat exchangers are made of metal materials. The thermal conductivity of different metal materials varies greatly, and the thermal conductivity of the same material at different temperatures is also different. As can be seen from the above table, silver has the highest thermal conductivity among commonly used materials, followed by copper and aluminum after silver. The fin material of the bimetal finned tube is made of aluminum, which is to take advantage of the high thermal conductivity of aluminum.

Carbon steel has a low thermal conductivity, but it is easy to obtain, so it has been widely used. There is a certain gap between the thermal conductivity of stainless steel and that of carbon steel. Many units manufacture stainless steel radiators according to the carbon steel design scheme, which is unscientific. The above table is a table of thermal conductivity of commonly used metal materials, which is an indispensable data when calculating the total heat transfer coefficient of a heat exchanger.